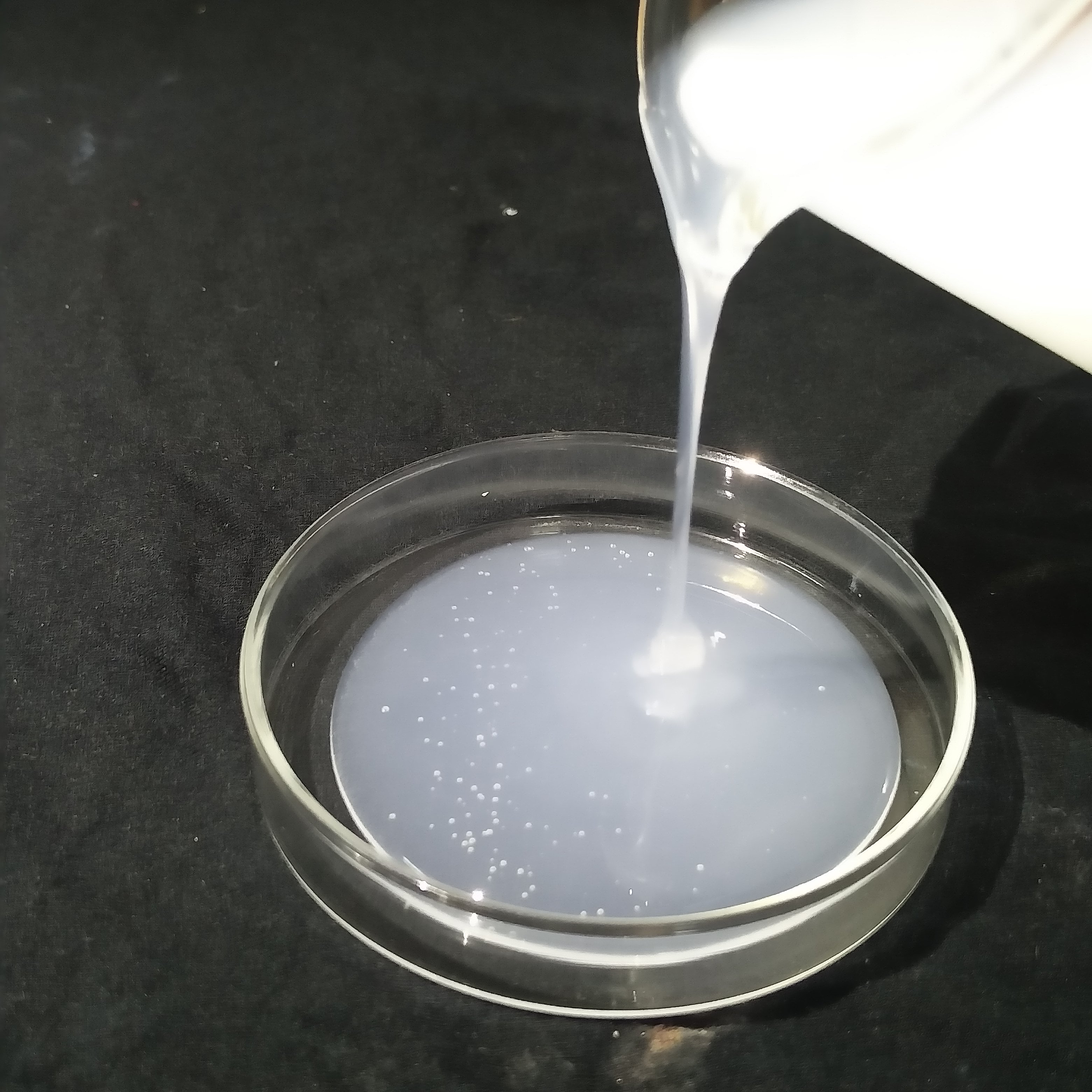

D.R.P SILICONE 204 & 222, NITIN INDL. COMPLEX, SUHASINI PAWSKAR MARG, DAHISAR (E), MUMBAI-400068. TELEFAX: - 022 – 28968673 * (OFF.): 28976177 * MOBILE: 9920397827 E – MAIL: - mrsilicones@gmail.com WEB: - www.mrsilicone.com MRSI-SD 100. SIMETHICONE OIL-100%. MRSI-SD 100 is a 100% Silicone Defoamer. It is widely used as a versatile Defoamer, in both general industrial applications. In medical and pharmaceutical applications, the requirements for this chemically inert silicone Defoamer is unique and exacting. INDUSTRIAL OPERATIONS Adhesives Paper coating processes. Agar. Paper production processes. Asphalt. Petroleum Pitch. Cutting Oils. Propane Gas. Detergents & soaps. Rubber Lattices. Fermentaion processes. Resins & Varnishes Filtration Processes Salt Solutions. Gas Scrubbing. Steel-Pickling solutions Hot Aqueous systems. Textile Processes. Insecticides. Vacuum distillations Oil Quench Baths Wool Fats. Polishes Wire-Drawing compounds HOW TO USE. AMOUNT. Amount is effective in very low concentrations. 1 to 50 gms per ton of foamer are sufficient to suppress most foam. For any new industrial application, the user may start with a concentration of 20 gms per ton, then increase or decrease this concentration until most economical use level, is established DIRECT APPLICATION AS SUPPLIED. In some applications, it may be wiped on process equipment to limit foaming level. In bottle filling machine, it is applied to the nozzles to knock down foam as it rises in the neck of the bottle, Similarly, a wiped on a application on the rim of processing vats prevents foam overflows. It may be wiped on a screen, which is then suspended over the surface of the foamer. Whenever the foam rises too high, it contacts the screen and is broken. SOLVANT DISPERSION. In most industrial applications, it is diluted with solvent, then added to foamier; dispersions may be made in Butyl Alcohol, Toluene, Xylem, Kerosene, Ethyl Ether, Chloroform and many other Solvents. Comparative tests using different diluents should be run if it is desirable to determine the most suitable and economical diluent to use for any particular process or product. Freshly prepared dispersion should be used for maximum efficiency SPECIFICATION FOR MRSI-SD 100 (100%) Sr.No TEST SPECIFICATION 1 Defoaming performance 15 Seconds maximum at 50 R.P.M. 2 Compound Activated Dimethyl Polysioxane 3 Colour Translucent 4 Stability Maximum 5% separation after 15 minutes at 1600 R.P.M 5 % ACTIVE 100% 6 Consistency. Syrupy 7 Sp. Gravity at 25°C 0.975 to 0.010 8 Viscosity. 2000 TO 4000 CST 9 Refractive Index at 25°C 1.402 to 1.406 10 Free Acid 0.025 to 0.04. 11 Moisture < 0.5 (Less than) 12 Suitable Diluent Aliphatic, Aromatic and Chlorinated Solvents 13 Self-Life 3 year.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

D.R.P SILICONE 204 & 222, NITIN INDL....

2018-01-30T07:54:55

D.R.P SILICONE 204 & 222, NITIN INDL. COMPLEX, SUHASINI PAWSKAR MARG, DAHISAR (E), MUMBAI-400068. TELEFAX: - 022 – 28968673 * (OFF.): 28976177 * MOBILE: 9920397827 E – MAIL: - mrsilicones@gmail.com WEB: - www.mrsilicone.com MRSI-SD 100. SIMETHICONE OIL-100%. MRSI-SD 100 is a 100% Silicone Defoamer. It is widely used as a versatile Defoamer, in both general industrial applications. In medical and pharmaceutical applications, the requirements for this chemically inert silicone Defoamer is unique and exacting. INDUSTRIAL OPERATIONS Adhesives Paper coating processes. Agar. Paper production processes. Asphalt. Petroleum Pitch. Cutting Oils. Propane Gas. Detergents & soaps. Rubber Lattices. Fermentaion processes. Resins & Varnishes Filtration Processes Salt Solutions. Gas Scrubbing. Steel-Pickling solutions Hot Aqueous systems. Textile Processes. Insecticides. Vacuum distillations Oil Quench Baths Wool Fats. Polishes Wire-Drawing compounds HOW TO USE. AMOUNT. Amount is effective in very low concentrations. 1 to 50 gms per ton of foamer are sufficient to suppress most foam. For any new industrial application, the user may start with a concentration of 20 gms per ton, then increase or decrease this concentration until most economical use level, is established DIRECT APPLICATION AS SUPPLIED. In some applications, it may be wiped on process equipment to limit foaming level. In bottle filling machine, it is applied to the nozzles to knock down foam as it rises in the neck of the bottle, Similarly, a wiped on a application on the rim of processing vats prevents foam overflows. It may be wiped on a screen, which is then suspended over the surface of the foamer. Whenever the foam rises too high, it contacts the screen and is broken. SOLVANT DISPERSION. In most industrial applications, it is diluted with solvent, then added to foamier; dispersions may be made in Butyl Alcohol, Toluene, Xylem, Kerosene, Ethyl Ether, Chloroform and many other Solvents. Comparative tests using different diluents should be run if it is desirable to determine the most suitable and economical diluent to use for any particular process or product. Freshly prepared dispersion should be used for maximum efficiency SPECIFICATION FOR MRSI-SD 100 (100%) Sr.No TEST SPECIFICATION 1 Defoaming performance 15 Seconds maximum at 50 R.P.M. 2 Compound Activated Dimethyl Polysioxane 3 Colour Translucent 4 Stability Maximum 5% separation after 15 minutes at 1600 R.P.M 5 % ACTIVE 100% 6 Consistency. Syrupy 7 Sp. Gravity at 25°C 0.975 to 0.010 8 Viscosity. 2000 TO 4000 CST 9 Refractive Index at 25°C 1.402 to 1.406 10 Free Acid 0.025 to 0.04. 11 Moisture < 0.5 (Less than) 12 Suitable Diluent Aliphatic, Aromatic and Chlorinated Solvents 13 Self-Life 3 year.

2018-01-30T07:54:55

Submit Your Enquiry